hardness test tensile strength|tensile strength hardness conversion : retailer The Brinell hardness number can be correlated with the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore . Brinell hardness test – Part 3: calibration of reference blocks". . WEB1 de jun. de 2023 · 1. Location. Tijucas, Santa Catarina,Brazil. 80% Straight, 20% Gay. margarida flor, Jul 23, 2023. #21. sagdcell said: espero que vc saiba que tentar vender conteudo dos outros aqui dá ban. e tbm é contra as regras incentivar ou pedir que as pessoas fiquem enviando coisa na dm. Só falei que tenho porque assinei.

{plog:ftitle_list}

Resultado da Fica a par de toda a programação do Sport Lisboa e Benfica e dos jogos de futebol e outras modalidades que terão transmissão em direto e exclusivo .

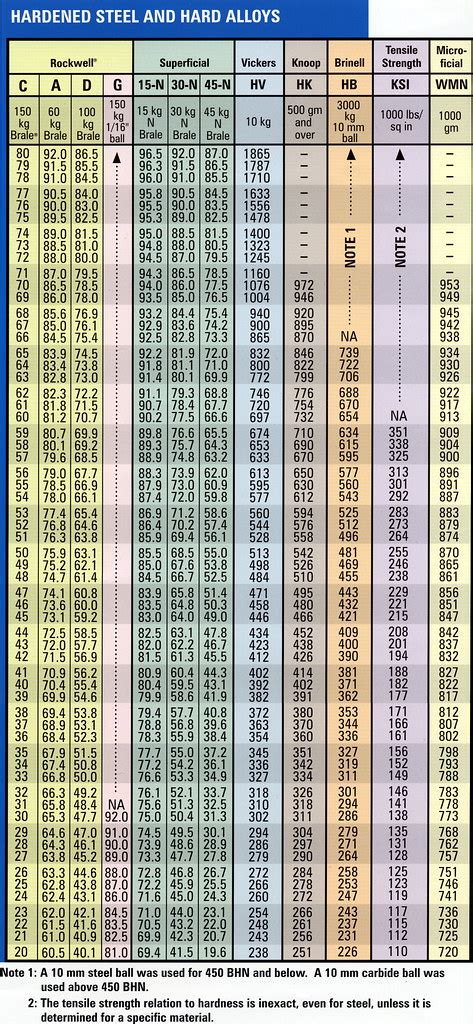

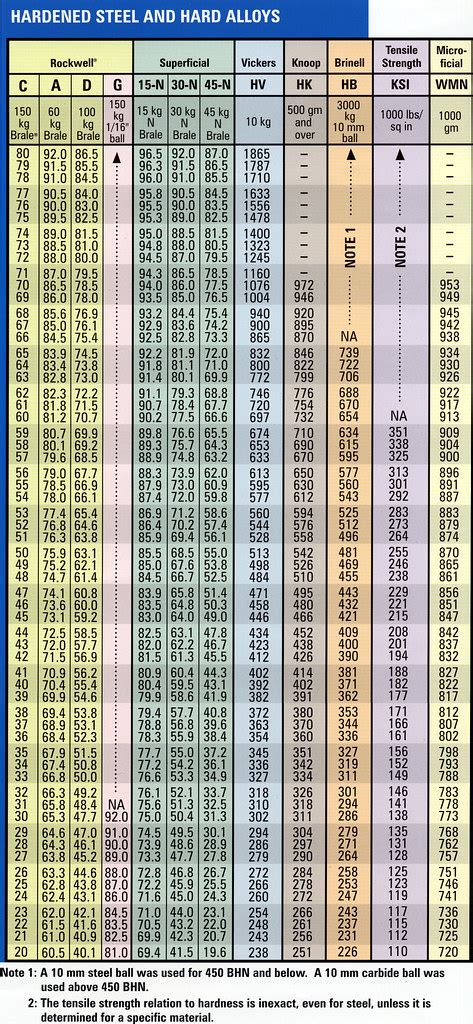

The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate.Conversion of hardness-to-hardness or hardness-to-tensile-strength values for unalloyed and low alloy steels and cast steel per. ISO 18265 - 2013. Hardness conversions are no substitute .

bottle vacuum test

The values of tensile strength converted by Rockwell hardness and Vickers hardness given in GB/T 1172-1999 are close to the test results. (3) Combined with the existing portable hardness testing instruments and .The Brinell hardness number can be correlated with the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore . Brinell hardness test – Part 3: calibration of reference blocks". .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.

The average results of the static tensile test for the individual sets, with basic descriptive statistics, are presented in Table 13. The strength parameters of the individual samples (i.e. yield strength R e and tensile strength R m) were correlated with the results of their hardness measurements. Afterwards, the relationships between them .

bottle vacuum tester

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or in notation) [1] is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the . When testing some metals, indentation hardness correlates linearly with tensile strength.The ISO 898-1, ISO 3506-1 and ASTM F606 standards describe tests on threaded fasteners (bolts, screws and studs) including steel screws and their mechanical and physical properties such as tensile strength, offset yield (minimum stress), elongation after fracture and hardness.. ISO 898-1 establishes the mechanical properties of fasteners made of carbon steel and alloy . Hardness testing is measuring a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. . It can however provide some valuable information about the strength and durability of a material, depending on the application it is intended for. . a ductility test uses a destructive tensile force to .Tensile strength = Bhn × 490 (for Brinell numbers larger than 175) The above formulas give the tensile strength in pounds per square inch for steels. These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing .

bottle warm to the touch drug test

Tensile strength from Brinell hardness can be roughly estimated by multiplying 3.45 and Brinell hardness is calculated using Tensile Strength = (3.45/9.8067)*Brinell Hardness.To calculate Tensile strength from Brinell hardness, you need Brinell Hardness (HB).With our tool, you need to enter the respective value for Brinell Hardness and hit the calculate button.

Steel hardness conversion chart: Shows equivalents using Brinell, Rockwell B and C and Vickers scales. These values are approximate and for guidance only. . Tensile Strength: 625-775 n/mm 2. 700-850 n/mm 2. 775-925 n/mm 2. 850-1000 n/mm 2. 925-1075 n/mm 2. 1000-1150 n/mm 2. 1075-1225 n/mm 2. 1150-1300 n/mm 2. 1550 n/mm 2. Hardness Brinell .Tensile Test ASTM standards 5 . • Relationship between Hardness and Strength 2 14.2 D F HK = ( ) 3.45 MPa 500 lb/in2 in TS Kh HB whereKh in = = = 15 Temperature Effect • Effect the all properties • Hot hardness • Recrystallization(0.5T m) .The tensile strength R m is determined with a tensile test (e.g. in accordance with the ISO 6892 series of standards (for metallic materials), or the ISO 527 series of standards (for plastics and composites)).. The tensile strength is calculated from the maximum achieved tensile force F m and the specimen cross-sectional area at the start of the test: .ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild steel is often compared to AISI 1018, A36 carbon steel is commonly hot rolled, while 1018 steel is commonly cold rolled.. Notes: There are two .

Tensile Testing: Used to determine tensile strength by stretching a sample until it fractures. The test measures the maximum load the material can withstand, typically reported in units like MPa (megapascals). . Hardness and tensile strength are related but not identical. In some cases, materials with high hardness also exhibit high tensile .

Method A is based on the increase in tensile stress during load application. In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this .

The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . The ultimate tensile strength is .

tensile to hardness conversion chart

tensile to hardness conversion

The tensile strength is the maximum stress or force required to break a material. The test specimens have been standardized by ASTM (American Society of Testing Materials). . What are the advantages and disadvantages of the Brinell hardness test? Advantages: It measures the hardness of a relatively large area, therefore, it is useful in .ISO 18265:2013 specifies the principles of the conversion of hardness values to equivalent values in other hardness scales and to estimates of tensile strength. It gives general information on the use of the conversion tables. . Annex H gives information about the effects of changes of the test procedure in the standards specifying the .

strength and tensile strength have been hardness testing because of its non- destructive (or semi destructive) nature, leaving behind only an indentation [8]. A simple equation that correlates tensile strength (TS) and hardness (H) can be stated as follows [9]: TS=H.k (1) where k .

tensile to hardness calculator

Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. The load is maintained constant for a .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . The ultimate tensile strength is the maximum on the engineering stress-strain curve.For some metals, like steel, hardness and tensile strength are roughly proportional (see ASTM A 370-68 Steel Tables). For this article, we’ll review the fundamentals of each, . Hardness testing is accomplished by lowering a probe with a hard (typically diamond) tip onto a material at a set force and measuring the amount of indentation that .

It is, therefore, of scientific interest to comprehend the connection between hardness and tensile strength for a variety of materials because (i) instead of time-consuming tensile testing .

In the Brinell Hardness Testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. . In general, with an increase in Brinell Hardness values the tensile strength also increases. There is an approximate formula that can be used to convert BHN to tensile strength (UTS) or vice versa. Examples of the Ultimate Tensile Stress of Various Materials. Steel: Steel is a mixture of iron (99%) and carbon (1%), giving the basic iron metal more strength and hardness.The tensile strength of steels is between 330 and 480 MPa. Steel, one of the most widely used metals in the world, is primarily utilized for structural purposes in the building of .

Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of CNC machining material or product design. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and .

bottle warmer test temperature

bottle water purity tests

Quina 6376: ninguém acerta as cinco dezenas. Prêmio acumula em R$ 9.000.000,00; Ninguém acerta os sete números da Timemania 2059; R$ 16.800.000,00 para o próximo .

hardness test tensile strength|tensile strength hardness conversion